|

|||||||||||||||

ST Microelectronics STR75x Port

|

|||||||||||||||

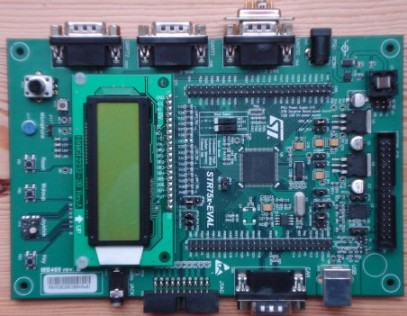

STR750 Evaluation Board

|

The STR750 ARM7 demo application is pre-configured for execution on the STR750 EVAL evaluation board from ST Microelectronics (instructions are provided should you wish to use an alternative development board).

The STR750 is an ARM7TDMI based microcontroller including CANBus, USB, and advanced analogue peripherals (amongst others).

The RTOS port and demo application presented on this page require the IAR Embedded Workbench development tools for ARM. The demo application can be compiled and debugged using the free 32KB limited KickStart version. Please ensure to be using the latest tools release.

The processor peripheral library provided by ST was used to facilitate development.

Note: If this project fails to build then it is likely the version of IAR Embedded Workbench being used is too old. If this is the case, then it is also likely that the project file has been (silently) corrupted and will need to be restored to its original state before it can be built even with an updated IAR version.

IMPORTANT! Notes on using the STR750 ARM RTOS port

Please read all the following points before using this RTOS port.See also the FAQ My application does not run, what could be wrong?

Source Code Organisation

The FreeRTOS download contains the source code for all the FreeRTOS ports so contains many more files than used by the STR750 port or demo application. See the Source Code Organization section for a description of the directory structure and information on creating a new project.A THUMB mode sample project is included for the STR75x IAR ARM7 port. The workspace rtosdemo.eww can be found in the Demo/ARM7_STR75x_IAR directory and should be opened from within the Embedded Workbench IDE.

The Demo/ARM7_STR75x_IAR/ST library directory contains the components of the ST peripheral library that are used by the demo application.

The Demo Application

The demo application is configured to create 22 fully preemptive tasks.Demo application hardware setup

The standard 'ComTest' tasks send and receive characters on UART0. The characters sent by one task need to be received by the another - an error being flagged if a character is received out of sequence or missed all together. A loopback connector is required on UART0 of the evaluation board for this functionality to operate (simply connect pins 2 and 3 together on the serial port connector labelled CN4).The demo application utilises the LEDs built onto the evaluation board so no further hardware setup is required. All jumpers and switches should remain in their default position.

The IAR workspace

The demo application workspace

The IDE workspace contains 4 folders:

- Demo Source

Contains the source files for the demo application. - Library Source

Contains the components of the ST peripheral library that are utilised by the RTOS kernel and the demo application. - RTOS Source

Contains the source files for the FreeRTOS real time kernel. - Startup

Contains the startup code and interrupt vector table definition.

Building the demo application

Two project configurations are provided. "Debug" contains minimal optimisation and can be used with the J-Link JTAG debug interface. "Release" has full optimisation and contains no debug information.Simply open the Demo/ARM7_STR75x_IAR/rtosdemo.eww workspace file from within the IAR Embedded Workbench IDE, ensure debug or release is selected as appropriate (circled in red in the image above), then select 'Rebuild All' from the IDE 'Project' menu.

Running the demo application

-

Ensure the J-Link JTAG debug interface is connected and that the target board is power up.

-

Select 'Debug' from the IDE 'Project' menu.

- The microcontroller flash memory will automatically be programmed and the debugger will break at the program entry point. Select 'Go' from the IDE 'Debug' menu to start the application executing.

Functionality

The demo application creates 19 of the standard demo tasks, a 'check' task, a 'print' task and the idle task.The 'print' task is the LCD 'gatekeeper'. That is, it is the only task that should access the LCD directly so is always guaranteed exclusive (and therefore consistent) access. The print task simply blocks on a queue to wait for messages from other tasks that wish to display text on the LCD. An arriving message unblocks the task, which writes the message contents to the LCD, before blocking once again. This functionality is included for demonstration purposes even though in this application there is actually only one task that generates display text.

The 'check' task is responsible for ensuring that all the standard demo tasks are executing as expected. It only executes every three seconds, but has the highest priority within the system so is guaranteed to get execution time. Any errors discovered by the check task are latched until the processor is reset. At the end of each cycle the check task sends either a pass or fail message to the 'print' task for display on the LCD.

When executing correctly the demo application will behave as follows:

- The LEDs LD2 to LD4 are under control of the 'flash' tasks. Each will flash at a constant frequency, with LD2 being the fastest and LD4 being the slowest.

- The LED LD5 is under control of the standard ComTest Tx task. Its state will toggle each time the ComTest Tx task transmits a character over the RS232 port.

- Most of the standard demo tasks do not update an LED so have no visible indication that they are operating correctly, and are therefore

monitored by the 'check' task.

"Pass" being displayed on the LCD indicates that the check task has never detected an error occurring in any task. The position of the text is shifted slightly each time it is displayed to provide a visual indication that the check task itself is still executing. The error detection mechanism can be tested by removing the loopback connector from the serial port while the demo is running, following which the "Pass" message should change to "Fail".

Configuration and Usage Details

RTOS port specific configuration

Configuration items specific to this port are contained in Demo/ARM7_STR75x_IAR/FreeRTOSConfig.h. The constants defined in this file can be edited to suit your application. In particular - the definition configTICK_RATE_HZ is used to set the frequency of the RTOS tick. The supplied value of 1000Hz is useful for testing the RTOS kernel functionality but is faster than most applications require. Lowering this value will improve efficiency.Each port #defines 'BaseType_t' to equal the most efficient data type for that processor. This port defines BaseType_t to be of type long.

Note that vPortEndScheduler() has not been implemented.

Interrupt service routines

The STR75x demo saves and restores the task context automatically prior to calling the user defined interrupt service routine C code. This is contrary to the STR71x port, where the context is saved and restored within the C code via the FreeRTOS provided macros. This alternative method is provided for demonstration purposes. It has the advantage of simplified syntax from a users perspective, but the disadvantage of slightly longer execution time for those interrupts in which a context switch is not performed.

An interrupt service routine must be written as an ARM mode C function.

For example:

static __arm void vAnISR( void )

{

/* ISR C code goes here. */

/* Clear the interrupt within the peripheral here. */

}

Often you will require an interrupt service routine to cause a context switch. For example a serial port character being

received may wake a high priority task that was blocked waiting for the character. If the ISR interrupted a lower priority

task then it should return immediately to the woken task. This can be performed by simply calling the macro portEND_SWITCHING_ISR() from

within the service routine, as demonstrated below:

static __arm void vAnISR( void )

{

/* ISR C code goes here. */

/* Clear the interrupt within the peripheral here. */

/* Pass in true to cause a context switch, or false to return

to the interrupted task. */

portEND_SWITCHING_ISR( pdTRUE );

}

See the function vSerialISR() within Demo/ARM7_STR75x_IAR/serial/serial.c for a complete example.

User defined interrupt routines must replace the ST provided stubs within 75x_vect.s (included in the startup folder of the project).

Switching between the pre-emptive and co-operative RTOS kernels

Set the definition configUSE_PREEMPTION within Demo/ARM7_STR75x_IAR/FreeRTOSConfig.h to 1 to use pre-emption or 0 to use co-operative.Compiler options

As with all the ports, it is essential that the correct compiler options are used. The best way to ensure this is to base your application on the provided demo application project file - as described in the Source Organization section.Execution Context

The RTOS scheduler executes in supervisor mode, tasks execute in system mode.NOTE! : The processor MUST be in supervisor mode when the RTOS scheduler is started (vTaskStartScheduler is called). The demo applications included in the FreeRTOS download switch to supervisor mode prior to main being called. If you are not using one of these demo application projects then ensure Supervisor mode is entered before calling vTaskStartScheduler().

The stack size of each necessary operating mode is configured using constants defined within the linker script file. It is not necessary to configure a stack for User/System mode.

SWI instructions are used by the real time kernel and can therefore not be used by the application code.

Memory allocation

Source/Portable/MemMang/heap_2.c is included in the ARM7 demo application project to provide the memory allocation required by the real time kernel. Please refer to the Memory Management section of the API documentation for full information.Serial port driver

It should also be noted that the serial drivers are written to test some of the real time kernel features - and they are not intended to represent an optimised solution. In particular they do not make use of the FIFO.

Tick Interrupt

The Time Base (TB) peripheral is used to generate the tick interrupt.

IAR compiler notes

The FreeRTOS source code has to be built with lots of different compilers. The IAR compiler has particularly strong (pedantic) source checking and generates several warnings when compiling the FreeRTOS source code.Unfortunately these warning cannot be fixed by modifying the source code as they predominantly relate to benign code that was added in order to fix warnings generated by other compilers (mainly relating to type casting). Some warnings have therefore been disabled in the project file.

NXP tweet showing LPC5500 (ARMv8-M Cortex-M33) running FreeRTOS.

Meet Richard Barry and learn about running FreeRTOS on RISC-V at FOSDEM 2019

Version 10.1.1 of the FreeRTOS kernel is available for immediate download. MIT licensed.

View a recording of the "OTA Update Security and Reliability" webinar, presented by TI and AWS.

FreeRTOS and other embedded software careers at AWS.